Collapsibles

Diploma in Mechanical Engineering Programme with intake of 60 students is started in 2009 in this Institute. Admissions to this Programme are conducted every year in month of June/July through centralized admission process (CAP) by Directorate of Technical Education (DTE). The Programme duration is of 3 years. The Programme is approved by AICTE (All India Council for Technical Education) and is affiliated to MSBTE (Maharashtra State Board of Technical Education). The department of Mechanical Engineering have highly qualified faculty and well equipped laboratories. The Vision and Mission statements of the department are as listed below.

To produce diploma level mechanical engineers to serve industry and society and to make them capable for life – long learning.

1) To impart Mechanical Engineering Knowledge to fulfill Industrial and Societal needs.

2) To produce Diploma level Mechanical Engineers capable for pursuing higher studies.

3) To promote Students for serving Industry and Society with high ethical values.

PEO-1:

Successfully practice or apply the principles of Mechanical Engineering in variety of employment areas.

PEO-2:

Achieve professional success with an understanding and appreciation of ethical behavior, social responsibility, and diversity, both as individuals and in team environment.

PEO-3:

Pursue life-long learning through professional practice, further graduate education or other training programs in engineering science or professional fields.

PO1 – Basic and Discipline specific knowledge:

Apply knowledge of basic mathematics, science and engineering fundamentals and engineering specialization to solve the engineering problems.

PO2 – Problem Analysis:

Identify and analyse well-defined engineering problems using codified standard methods.

PO3 – Design/ development of solutions:

Design solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs.

PO4 – Engineering Tools, Experimentation and Testing:

Apply modern engineering tools and appropriate technique to conduct standard tests and measurements.

PO5 – Engineering practices for society, sustainability and environment:

Apply appropriate technology in context of society, sustainability, environment and ethical practices.

PO6 – Project Management:

Use engineering management principles individually, as a team member or a leader to manage projects and effectively communicate about well-defined engineering activities.

PO7 – Life-long learning:

Ability to analyse individual needs and engage in updating in the context of technological changes.

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO1 – Modern Software Usage:

Use latest Mechanical engineering related software for simple design, drafting, manufacturing, maintenance and documentation of mechanical engineering components and processes.

PSO2 – Equipment and Instruments:

Maintain equipment and instruments related to Mechanical Engineering.

PSO3 – Mechanical Engineering Processes:

Manage Mechanical engineering processes by selecting and scheduling relevant equipment, substrates, quality control techniques, and operational parameters.

| SR NO | NAME OF FACULTY | Designation | QUALIFICATION | E-mail Address |

|---|---|---|---|---|

| 1 | Shri. D.S.Dhoble | H.O.D | M.TECH | dsd_dhoble@yahoo.co.in |

| 2 | Shri. V.D.Thakur | Lecturer | M.E.(Thermal Power Engineering) | vdthakur2000@gmail.com |

| 3 | Shri. V.S.Paraskar | Lecturer | M.E.(Metallurgy) | vparaskar@rediffmail. com |

| 4 | Shri. A.J.Deshmukh | Lecturer | B.E.(Mechanical) | arvindjdeshmukh@gmail.com |

| 5 | Ku. S.S.Dandge | Lecturer | Ph. D. (Perusing), M.Tech.( Thermal) | shruti.dandge@gmail. com |

| 6 | Shri. A.P.Chavan | Lecturer | M.E.( Production Appeared) | amitchavanmzr@gmail.com |

| 7 | Shri A.E. Ghurde | Lecturer | ME(THERMAL) | anup.ghurde27@gov.in |

| 8 | Shri. A.P.Ingole | Lecturer | M.E.( Production Appeared) | amol24ingole@gmail.com |

| 9 | Shri. S.B.Chavan | Lecturer | B.E.(Mechanical) | shyamgpkhamgaon@gmail.com |

| 10 | Shri. P.B.Chavan | Lecturer | M.E.(Design) | chavanprashant007@gmail.com |

Supporting Staffs

| SR NO | NAME OF FACULTY | Designation | QUALIFICATION | E-mail Address | |

|---|---|---|---|---|---|

| 1 | Shri. V. N. Dhoran | Tech. Lab. Asst. | B.E. (Chemical) | vinoddhoran@gmail.com | |

| 2 | Shri. D. K. Kahane | Tech. Lab. Asst. | D.M.E | dkkahane@gmail.com | |

| 3 | Shri. L. S. Dhone | Lab. Attendant | B.A. |

|

Portfolios/Program wise Committee

Departmental Academic Calender-2021-2022

DETAILS OF CO-CURRICULAR ACTIVITY

Academic Year : 2021-22

Program : Mechanical Engineering

|

Sr. No. | Type of Activity & Details (Paper Presentation/Project/Quiz/etc.) | Date | Number of Participating Student | Organizing Body and Organizing Institute | Awards (Winner/Participation ) | Level(State/National/etc.) |

| 1 | Technical quiz competition | 13/10/2021 | 56 | G P Gondia | Participation | State |

| 2 | TechnoTrivia 2021 | 26/09/2021 | 33 | Prof Ram Meghe Institute, Badnera | Participation | National |

| 3 | Online Paper Presentation Competition | 18/11/2021 | 02 | G P Aurangabad | Participation | State |

| 4 | Quiz Competition on Advanced Manufacturing Processes | 15/01/2022 | 44 | G P Amravati | Participation | State |

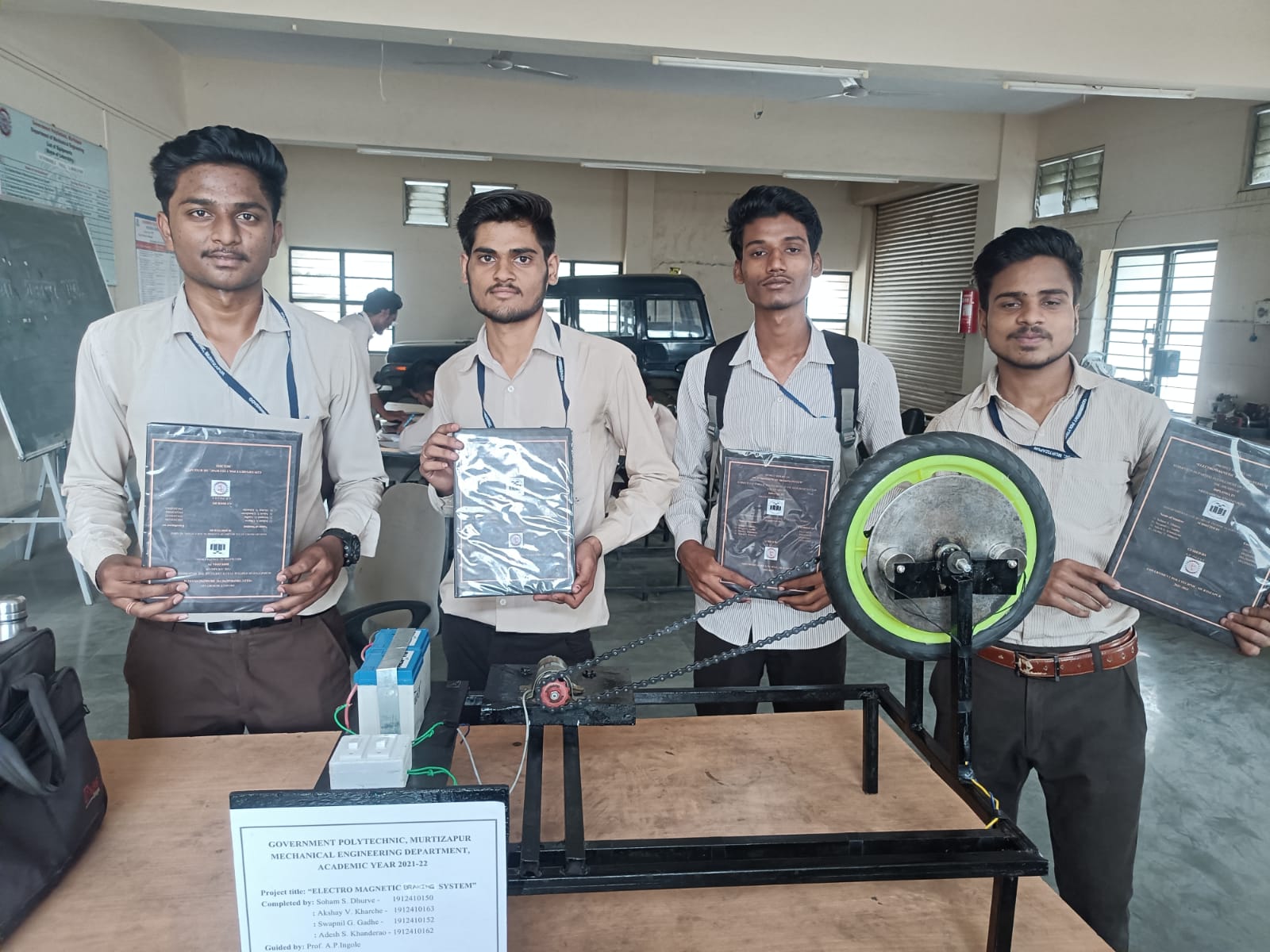

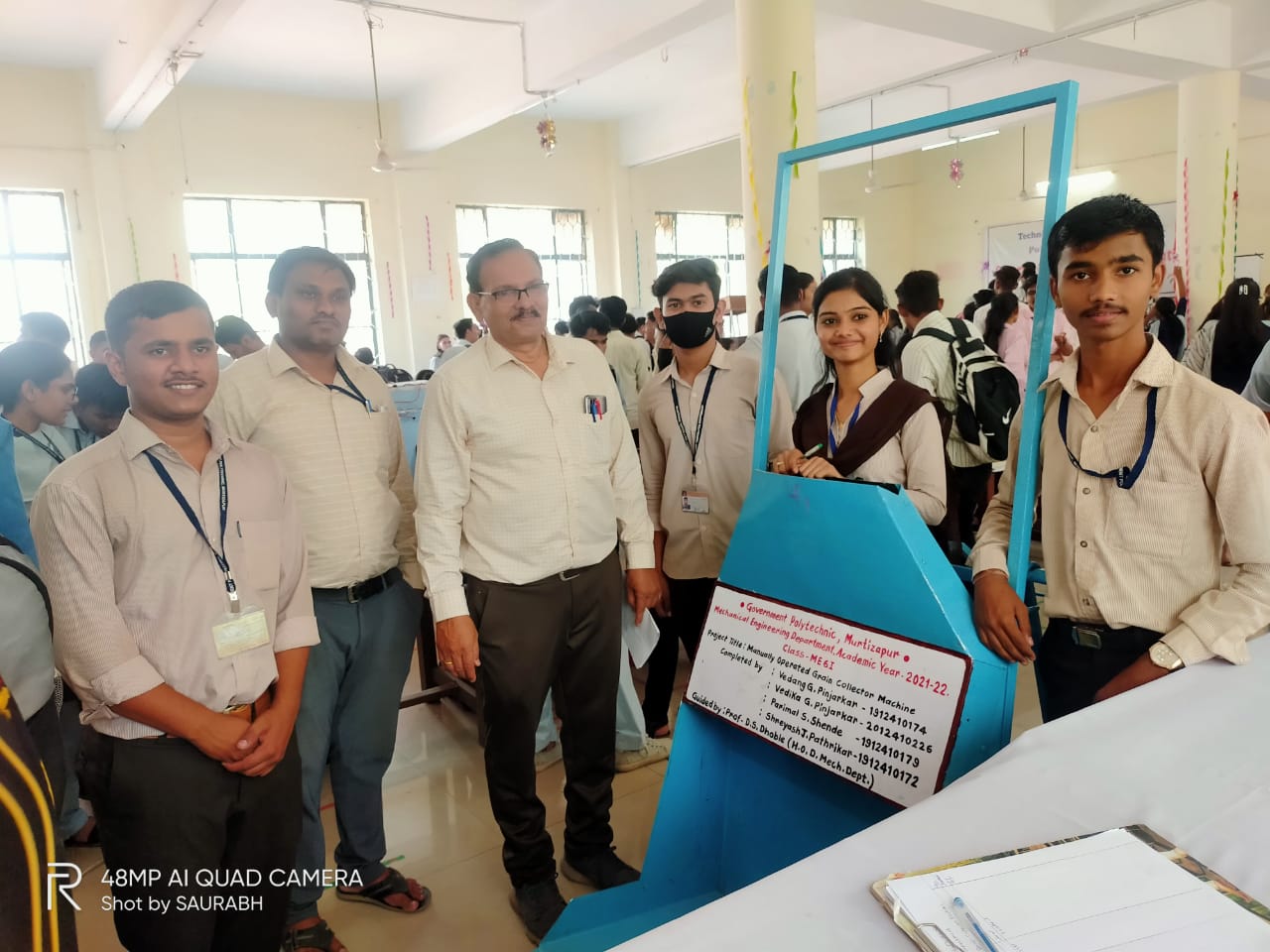

| 5 | Technical Project Competition | 13/04/2022 | 08 | G P Amravati | Participation & Winner | Regional |